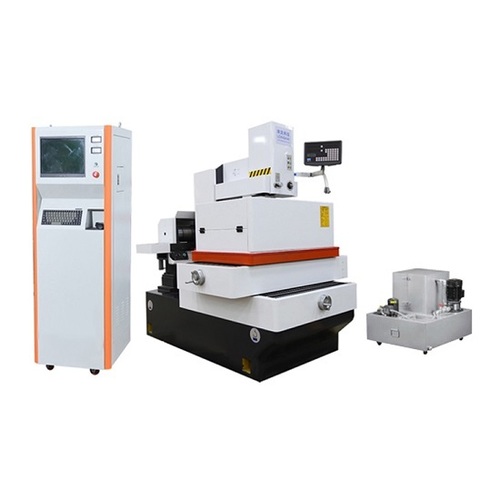

LK-800 Stepper mid-speed WEDM machine

Product Details:

- Product Type Stepper medium speed wire cut machine LK-800

- Material Steel

- Type Automatic Cutting Machine Metal Cutting Machine

- Weight (kg) 3800 Kilograms (kg)

- Computerized Yes

- Automatic Yes

- Control System PLC Control

LK-800 Stepper mid-speed WEDM machine Price And Quantity

- 986000-990000 INR/Set

- 986000.00 - 990000.00 INR/Set

- 1 Set

LK-800 Stepper mid-speed WEDM machine Product Specifications

- 350 Millimeter (mm)

- White

- Water Chiller

- PLC Control

- 380 Volt (v)

- Yes

- Electric

- Stepper medium speed wire cut machine LK-800

- 3800 Kilograms (kg)

- Steel

- Semi Automatic

- Automatic Feeding High Torque Low Noise Good Quality High Efficiency Low Energy Consumption Environmental Friendly

- Automatic Cutting Machine Metal Cutting Machine

- Yes

- 2410*2060*2250 Millimeter (mm)

LK-800 Stepper mid-speed WEDM machine Trade Information

- shanghai,China

- Letter of Credit at Sight (Sight L/C) Telegraphic Transfer (T/T)

- 100 Set Per Month

- 1-2 Week

- Contact us for information regarding our sample policy

- Wooden

- Australia North America South America Eastern Europe Western Europe Middle East Central America Asia

- All India

- CE

Product Description

Stepper Mid-speed WEDM machine

1Characteristics.

1The main machine adopts high quality 250 resin sand, which has been tempered many times to eliminate internal stress and keep the accuracy of machine tool unchanged for a long time.

2Filament barrel motion bearing adopts all imported precision bearing, which has longer service life. The guide wheel adopts special high precision guide wheel and all imported bearings, which greatly increases the service life.

3The filter device of slow-moving silk water tank, special water-based cutting fluid and multi-layer filtering system are adopted. The self-suction pump has better performance and longer service life, which lays a foundation for high precision and roughness of the processing surface.

4One-stop automatic centralized oil supply device can lubricate X, Y guideways, screw rods, barrel guides and screw rods, and ensure the service life of machine tools.

5The system is a complete set of WEDM solutions. AutoCut system is composed of AutoCut system software, motion control card based on PCI bus, high reliability, servo drive control motherboard, AC high frequency discharge board and sampling circuit. AutoCut system software includes AutoCAD WEDM module, NCCAD (including WEDM module), CAXA AutoCut plug-in and machine tool control software.

In order to ensure the accuracy of each machine, Longkai uses Renishau laser interferometer to check the positioning accuracy and repetitive positioning accuracy of the equipment. The high-configuration guide wheel and guide nozzle are adopted in the silk hauling system. The reasonable layout completely solves the problem of single side loosening and makes the machined surface achieve uniform roughness.

Long-life moving parts:

1.The X, Y and Z axes are all equipped with high precision ball screw and imported rolling linear guide, which can run smoothly and keep the accuracy of the machine tool.

2Imported bearings are used in all moving bearings of machine , so that the reliability and durability of machine tool processing accuracy are higher and the long-term interests of customers are guaranteed.

3.The guide nozzle adopts the design of slow-moving wire. The UV axis is fixed and the guide nozzle can rise and fall automatically, so that it can be as close as possible to the workpiece's machined surface, prevent the molybdenum wire from shaking again, avoid the line marks on the cutting surface, and greatly improve the accuracy and roughness of the machined surface.

4The tightening system uses two-way automatic tightening device to tighten molybdenum wire in real time. The unevenness and accuracy of the processing plane caused by the inappropriate tightness of molybdenum wire in the process of processing are thoroughly solved.

1.The guide wheel adopts specially made gem guide wheel and customized sprinkler plate. Replacement can automatically return to the origin, greatly reducing the difficulty of replacing vulnerable parts, and facilitating the use of customers.

6.The imported linear guide rail and the imported switch are used for the barrel guide rail and the commutation switch to ensure the stability, high precision and long-term reliability of the barrel at high and low speeds.

Main Characteristics of Stepper WEDM machine

1Graphic driving technology reduces the labor intensity of workers, improves the efficiency of workers, and reduces the chance of misoperation.

2For users of Windows XP and other versions, the software is easy to use, that is to say, learning is learning.

3Directly embedded in AutoCAD, NCCAD, CAXA and other versions of software, the integration of CAD/CAM is realized, and the machinable object of WEDM is expanded.

4Four-axis linkage control technology is used in the processing of taper workpiece; three-dimensional design of processing trajectory; and compensation of guide wheel radius, wire diameter, unilateral discharge gap and elliptical error of large taper to eliminate the theoretical error of taper processing;

5.With multi-card parallel technology, one computer can control multiple WEDM machines at the same time.

6It can carry out multiple cutting, with the function of user-maintained process library, intelligently control the processing speed and parameters, so as to improve the surface finish and dimensional accuracy, and make multiple processing simple and reliable.

7This software optimizes the processing of super-thick workpiece (more than 1 meter) to make its tracking stable and reliable.

8Connection network management: In order to facilitate the operation of one person and multiple computers, drawing input and export, equipment can realize network connection.

2technical parameter Scarlet data are different for each item.

Performance of thewhole

|

|

Equipmenttype |

Unit |

LK-800 |

|

|

Fuselage |

HostSize(Length*Width*Height) |

mm |

2410*2060*2250 |

|

|

Totalweight |

kg |

3800 |

||

|

Workbench |

Workbenchsize(width*length) |

mm |

1180*750 |

|

|

Travel |

X-axistravel |

mm |

630 |

|

|

Y-axistravel |

mm |

800 |

||

|

Z-axistravel |

mm |

300 |

||

|

CNCPowerSPulsewidth |

us |

1-250 |

||

|

Wirespeed |

|

0-3 |

||

|

Cuttingnumber |

time |

1-7 |

||

|

MiniMechanicalDrivingEquivalent |

um |

1 |

||

|

PulseResolution |

um |

0.4 |

||

|

Processing capacity |

Spindlestroke(electricallyadjustable) |

mm |

250 |

|

|

Max.cuttingslope/workpiecethickness |

|

630/80mm |

||

|

kg |

1200 |

|||

|

Machiningaccuracy |

LocationaccuracyX/Y |

mm |

0.01 |

|

|

RepeatedpositioningaccuracyX/Y |

mm |

0.005 |

||

|

Multi-toolCuttingAccuracy |

mm |

0.005( 40mm,Cut one and repair two. MaterialSKD11orCr12,HRC58 |

||

|

um |

Ra1.0(MaterialSKD11 or Cr12,HRC58 |

|||

|

|

mmmin |

220 |

||

|

Commoncuttingefficiency |

mmmin |

140 |

||

|

Max.ProcessingCurrent |

A |

6-8 |

||

|

Machine |

Processing efficiency |

No-loadVoltageofMachiningPowerSupply |

V |

100 |

|

Powerconsumption |

kw |

2.3 |

||

|

Wire traveling system |

Electrodewirediameter |

mm |

0.12-0.2 |

|

|

Wirebarreltravelingspeed |

|

frequency control |

||

|

Tighteningmethod |

|

Two-way automatic tightening |

||

|

Wiretravellingspeed |

m/s |

3-12 |

||

|

Working groove |

Filtrationaccuracy |

um |

10 |

|

|

Slow-Walking Filtration |

||||

|

Workingfluid |

|

Special cutting fluid |

||

|

Environment andelectricity |

E380V10% / 50/60Hz / 2kVA |

|||

|

TT15-30 / humidity40-80% |

||||

|

Pkpa |

86-106kpa |

Equipment accessories

|

Machine |

NO. |

Name |

Discription |

Origin |

|

body |

1 |

Machine bed |

Quality 250 Resin Sand Casting |

China mainland |

|

2 |

X.Y Axis Screw |

Precision ball screw |

Taiwan |

|

|

3 |

X-axis and Y-axis guideways |

Precision linear guide |

TBI |

|

|

4 |

Oil injection pump |

Computer automation |

China mainland |

|

|

5 |

Guide wheel |

Thickened Gemstone Guide Wheel |

Customized in China mainland |

|

|

6 |

Ruby guide nozzle |

Patented product |

China mainland |

|

|

7 |

Reversing switch |

OMRON |

Japan |

|

|

8 |

Filtration system |

Filtration mode of slow filament |

Longkai |

|

|

Power Supply |

9 |

Power Control Cabinet |

High Performance Control Power Supply |

AutoCutSystem |

|

10 |

IPC |

Fan-free dual-core CPU (4 threads) |

Longkai |

|

|

11 |

Industrial Display Screen |

AU Optronics |

Taiwan |

4Outbound Documents

|

S/N |

name |

QTY |

unit |

P.S. |

|||||||

|

Medium speed machine |

2 |

NC control cabinet |

3 |

Filtration tank |

4 |

Packing Technical Documents |

5 |

Hold-all |

1 |

|

|

Other Products in 'Medium speed STEPPER wire cutting machine' category

|

SUZHOU LONGKAI ELECTROMECHANICAL TECHNOLOGY CO.,LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry